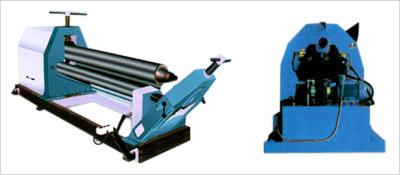

| Hydraulic / Mechanical 3/4 Roll

Plate Bending Machine |

|

| |

Specifications: |

| |

The Pinch Cum Puramid Principle |

|

- The machine based on this principle combine the advantages of three roll pyramid type, three roll initial pinch type and four roll

pinch type machines.

- Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains.

- An error in pre pinching can be corrected even after the shell is completed.

- It can pre-pinch and roll the plate without removing the plate from machine after first insertion.

- Inclined movement of bottom rolls provides wider bending span as the plate thickness increases, and better grip in thinner plates.

|

| |

Cone Bending |

|

- The Machine has inherent feature for conical bending without any extra attachments. The two bottom rolls are inclined by disengaging the dog clutch by lever fitted on the machine. Even pre-pinching of cones can be done.

|

| |

Salient Features |

|

- Top roll drive for rolling thin plates.

- Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains.

- Plate Squaring(aligning) arrangement.

- Small dia. Top roll for small shell rolling (for reduced capacity).

|

| |

The Symmetrical Three Roll Principle of Plate Pre-Prinching & Rolling |

| |

|

The plate is first lightly rolled over its full length. One of the bottom roll is brought near the top roll and plate edge is brought close to the tangent point. By lifting the other bottom roll, plate edge is pre-bent (pre-pinched) |

|

|

The Positions of bottom rolls are reversed (interchanged) for pre-bending second edge of the plate. Note that both the edges are pre-bent without turning the plate around. |

| |

|

|

|

|

|

The rolls are brought in pyramid formation and cylinder is completed. Note that an error in pre-pinching can be corrected even at this stage. |

|

|

|

| |

TOP |